DWC108Pro 8pc. 2D-3D Carving Bit Collection Set

DWC108Pro 8pc. 2D-3D Carving Bit Collection Set

This 8 piece collection is Specially designed for 2D and 3D CNC profiling and carving in plastic aluminum & wood with the DWC2440 Digital Wood Carver, DWC1824 Mini Carver & Our Commercial Line CNC Units.

Set Includes:

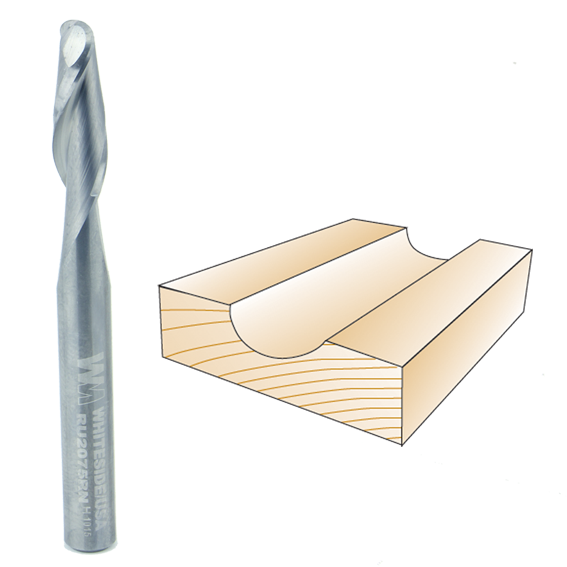

DWC01- CNC 2D and 3D Carving 5.4 Deg Tapered Angle Ball Tip 1/16 Dia x 1/32 Radius x 1 x 1/4 Shank x 3 Inch Long x 2 Flute Solid Carbide Up-Cut Spiral Router Bit

DWC02- CNC 2D and 3D Carving 3.6 Deg Tapered Angle Ball Tip 1/8 Dia x 1/16 Radius x 1 x 1/4 Shank x 3 Inch Long x 3 Flute Solid Carbide Up-Cut Spiral Router Bit

DWC04 Carbide Tipped V-Groove 90 Deg x 1/4 Dia x 1/4 Inch Shank

DWC05 Carbide Tipped V-Groove 60 Deg x 1/4 Dia x 1/4 Inch Shank

DWC06 Carbide Tipped V-Groove 30 Deg x 1/4 Dia x 1/4 Inch Shank

DWC07- Solid Carbide Spiral Plunge 1/4 Dia x 1 x 1/4 Inch Shank Down-Cut

DWC08- Solid Carbide Spiral Plunge 1/8 Dia x 1 x 1/4 Inch Shank Up-Cut

V-Groove Router Bits

Cut decorative V-Grooves and lettering on signs with these V-Groove bits. Use with an edge guide to chamfer and bevel edges. Can be used with handheld, table-mounted and CNC routers.

Excellent for cutting:

20lbs High Density Urethane

Acrylic

Composites

Composite Decking

Foam

Laminate

MDF/HDF

Melamine

Plywood

PVC Plastic

Sign Board

Solid Surface

Veneered Plywood

Wood

Xanita® Board

UpCut & DownCut Spiral Bits

Specially designed for speed and finish when working with solid hardwood. The combination of acute spiral flute shear angles with face ground helix yield high feed rates fast plunge action quick direction changes deep penetration and mirror finish. Recommended RPM 20 000-21 000.

Tools are manufactured with high balance that allows them to run up to 24,000 RPMs. Adjust your chip load and feed rate accordingly.

Applications:

A perfect bit for 3D carving

Precision 2D and 3D large scale carving

Great for deep profiling

Dimensional signage

3D millwork

2D and 3D contouring, profiling, modeling and pattern making for cabinetry, sign making, furniture making and jewelry mold making

Perfect for model-makers on large 3D milling profiles in abrasive EPS foam and other materials

Excellent for cutting:

Acrylonitrile-Butadiene-Styrene (ABS)

Acrylic

Acrylic Stone

Aluminum

Brass

Bronze

Composite

Copper

Corian

Coroplast®*

Dibond®

Ethafoam***

Ethylene-vinyl Acetate Foam (EVA)

Expanded Polypropylene (EPP)**

Expanded Polystyrene Foam (EPS)

Extruded Polystyrene Foam (XPS)

Fiberglass

Fiberglass PCB Board

Foam Board

Graphite

HDPE

HDU

20lbs High Density Urethane

Lexan™

MDF/HDF

PALFOAM™

Phenolics

Phenolic Composites

Plastics

Poly (methyl methacrylate) (PMMA)

Polyethylene Foam***

Polylam***

Polyurethane Foam

PVC

PVC Foam Board

Sign Board

Sign Foam

Titanium

Tooling Board

Wood

XPE (Cross Linked Polyethylene) Foam

*A soft plastic cardboard made with super soft, super flexible PVC.

**Expanded polypropylene (EPP) is a foam form of polypropylene.

***Ethafoam, Polyethylene, and Polylam are durable, flexible, closed-cell foams with excellent memory.

Milling Plastics

In a milling application, all plastics tend to behave differently so attention must be paid first and foremost to heat input, as that greatly impacts surface finish and chip control. Some of Amana Tool carving tools, as you can appreciate have a very small diameter therefore any material chip-loads need to reflect that small size. It can however withstand RPM’s up to 60,000 RPMs. A directed air-blast to keep chips away along with cooling the tool and work piece are always welcome.

Suggested starting spindle speed might be 18,000 RPM, there needs to be some experimenting on the part of the programmer to best find an acceptable finish.